SpaceInvader Climate Report 2021

SpaceInvader documents a reduction of 6,645 tons CO2 from clients’ use of pallet racks in 2021.

The earth’s climate is challenged like never before, and we need to find solutions that are proven to work and implement them fast. We have one of those solutions at SpaceInvader. We worked with Kobra Advice to put our money where our mouth is and the result is our climate report for 2021.

Beyond documenting our own green balance sheet, the report also contains the climate model we use, Green Space Impact (GSI), which calculates how much CO2 our clients save by using SpaceInvader. Producing this report was both a costly and labor-intensive affair, but it’s something we feel is of great strategic importance. We want to prove to our clients what we already know – the CO2 reduction our solution offers is real and attainable.

We were put in the world to make transportation more sustainable, and the climate model is an eyeopener for our partners when they see the CO2 savings that are possible. When the majority of companies discuss the green transition of heavy road transports, they usually focus on greener fuels, electrification, etc. Very few consider the great CO2 savings that are possible from something as simple as making fewer runs. We need to start having this conversation, for the sake of the environment, costs and congestion on our roads. There’s so much to be gained.

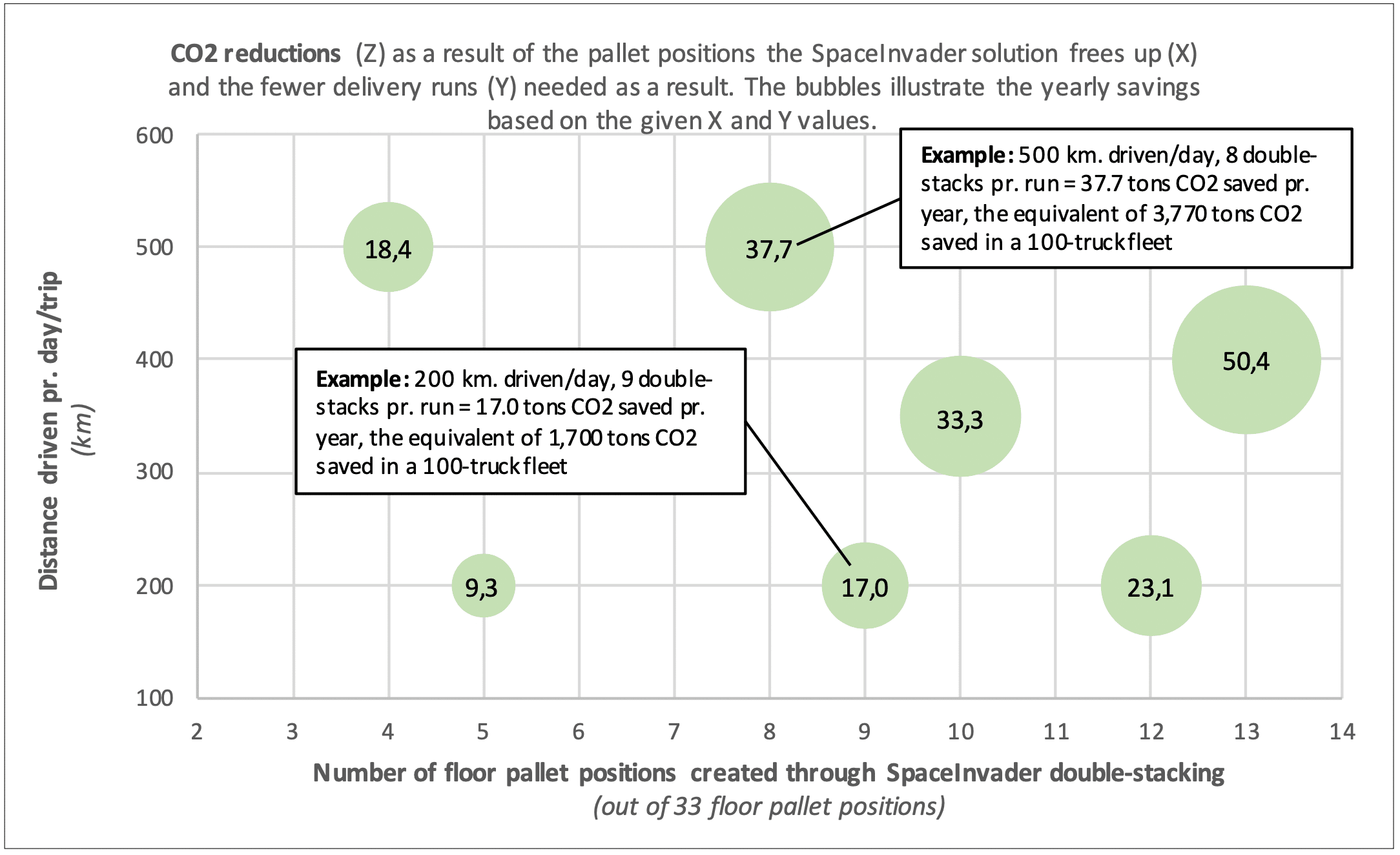

Let me give you an example: In the grid below, we’ve calculated how much CO2 a client can save with every truck per year by using SpaceInvader. (The model is based on a client who drives 24-ton trucks with 33 pallet positions and a diesel consumption of 3.1 km/liter.) If SpaceInvader on average frees up merely 8 of the 33 pallet positions through double-stacking of pallets, the yearly net savings reach 37.7 tons CO2 and 12,000 liters of diesel per truck based on a daily distance of 500 km. driven per day. (180,000 km. per truck per year)

So if we just imagine a carrier who employs 100 trucks in their daily operations, the collective yearly savings grow accordingly. 100 trucks reduce the carrier’s carbon footprint by 3,770 tons CO2 yearly. And as a company this carbon footprint is your footprint, as it’s included in your so-called scope 3 emissions – something everyone in the supply chain must work together to reduce.

And the good news: there’s money to be made by getting the transition underway

There’s also the added benefit that our solution reduces costs as well as CO2. We’ve seen logistics professionals and carriers save somewhere between 15-30% by systematically optimising their freight. And with an additional carbon tax on the way starting in 2025, rumoured to be 750 DKK per ton, a typical optimization of 15% calculated on the above example would see potential yearly savings hit 280,000 DKK per year for every single truck.

I hope you’ve been inspired to take action, because our environment demands it, and we need to move fast. The good news is the payoffs begin on day one. If you want to know more about how we work with our clients to reduce CO2 and optimise capacity, you’re welcome to give me a call. I’m attaching our climate report to this message – happy reading!

Best wishes

Steen Frederiksen

CEO