Decarbonise logistics now: Rely on proven tools, not tomorrow’s promises

The Urgent Need to Rethink Supply Chains

The environmental challenges of today are clear and present. From wildfires spreading in numerous countries to devastating hurricanes, floods, and the rise of sea surface temperatures, our planet is sending a clear message. Last year marked a particularly alarming sign as Europe witnessed its hottest summer on record. The data is undeniable: continued greenhouse gas emissions mean more record-breaking climate events that will greatly impact our societies and ecosystems.

In this urgent context, global supply chains play a significant role, often overlooked amid other issues. These extensive networks, which often span across various countries and continents, are at a critical point. They not only contribute to global warming and environmental challenges but are also at risk from them. As central structures in today’s global commerce, the transformation of supply chains is not merely about recognising environmental duty – it represents an essential shift in the way businesses operate.

Both a challenge and an opportunity

Addressing the dual mandate of decarbonising while upholding resilient operations is the call of the hour. Delving into the numbers, it’s evident that supply chains often shoulder a significant environmental burden. According to McKinsey, “the typical consumer company’s supply chain creates far greater social and environmental costs than its own operations, accounting for more than 80 percent of greenhouse-gas emissions and more than 90 percent of the impact on air, land, water, biodiversity, and geological resources”.

Empirical evidence supports this approach. A joint study by the World Economic Forum (WEF) and Boston Consulting Group (BCG) posited that nearly 40% of emissions embedded in global supply chains could be eradicated using current, accessible strategies. The best part? This can be achieved with minimal effects on end-consumer costs. However, there is still a disconnect between the potential of these solutions and their actual implementation in the industry.

Globally operating and fully sustainability committed companies confirm Mckinsey’s findings with their scope 3 reporting. Examples are Carrefour with 98%, and Nestlé with 95%. And if we narrow down to logistics related emissions specifically – let’s dive into Nestlé as an example: 7.8 % of their scope 3 emissions come from logistics. For businesses with complex supply chains, like Nestlé, this situation poses both challenges and opportunities.

Optimising freight capacity is a low-hanging fruit

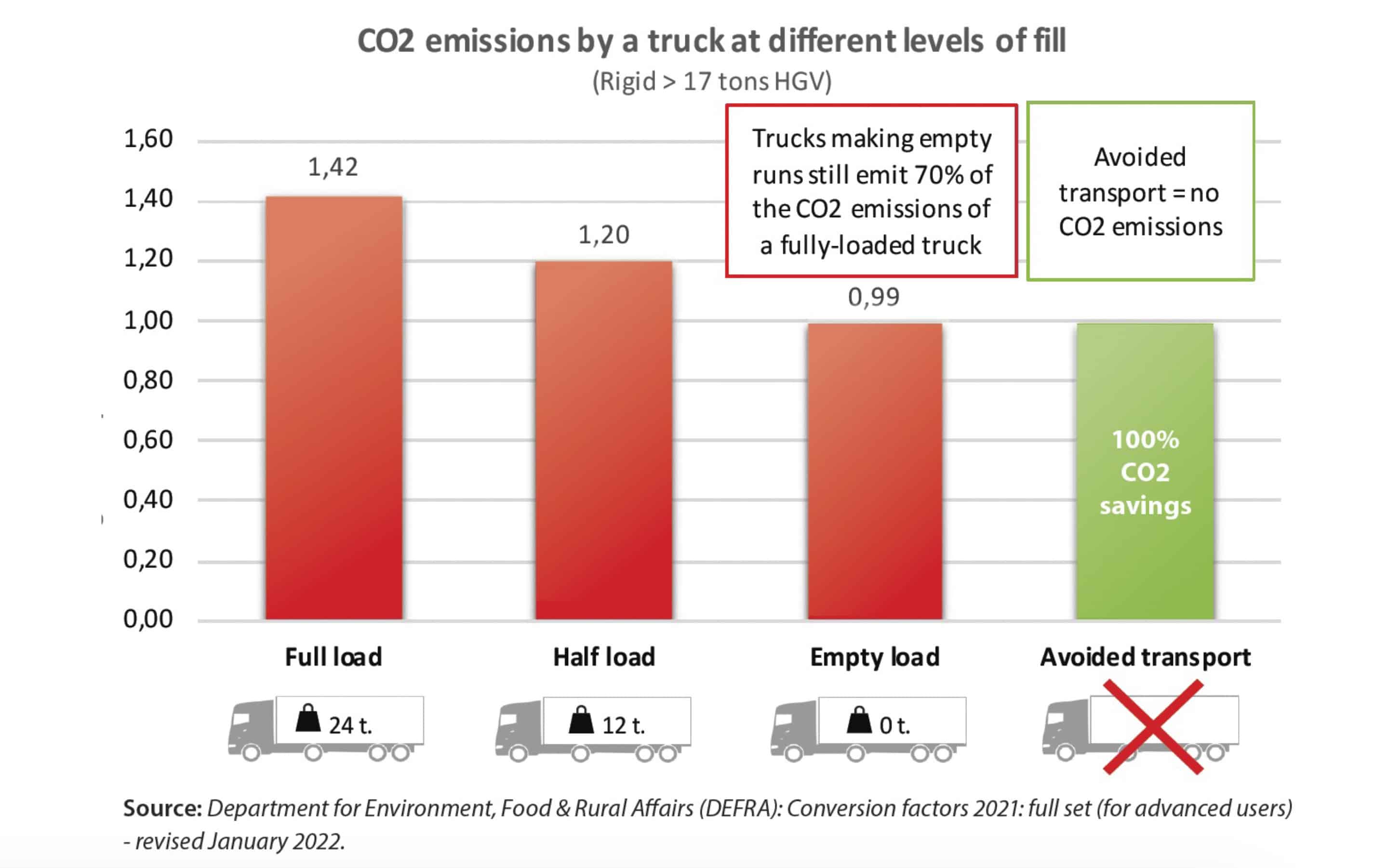

As an innovative, green-tech based company focused on helping companies optimise freight capacity throughout their supply chains, we believe it’s crucial to explore how transportation and logistics can be decarbonised in the short term. The illustration below shows that trucks making empty runs still emit 70% of the CO2 that a fully loaded truck emits. A sad fact that is not sustainable and must be changed to the better.

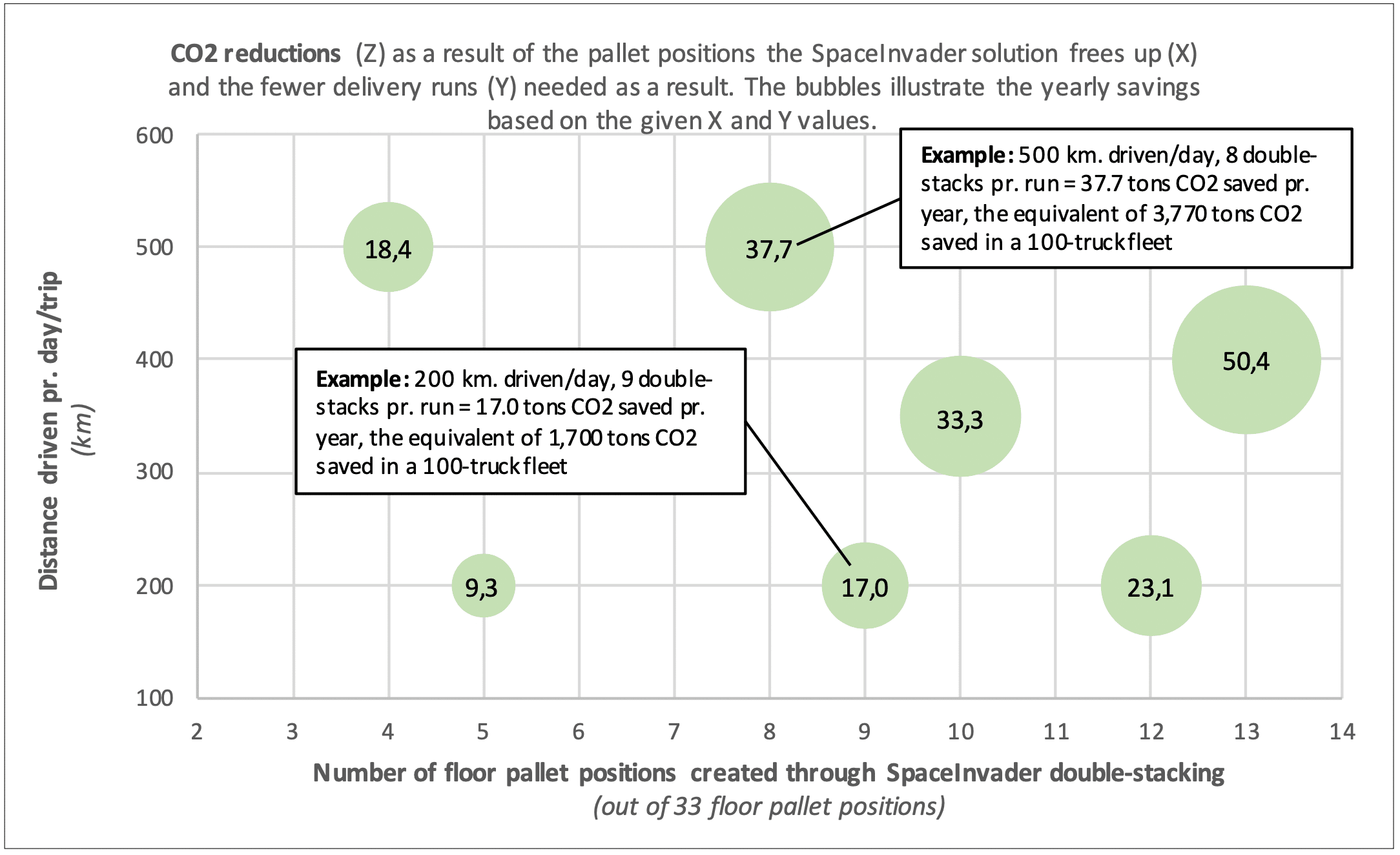

In SpaceInvader we help companies adjust and innovate their operations with the aim to ensure not just resilience but also a more sustainable future. For many business leaders, a pressing question is: Can we make meaningful, sustainable changes to supply chains without facing huge costs? If you ask us, it is a clear ‘yes’! In other words, capacity can be optimised by saving delivery runs and making sure that trucks are loaded to the extent possible. That is a very low hanging fruit, guaranteeing savings in both fuel cost and CO2-reductions. Industry experts also suggest that cutting CO2 can cut costs at the same time, bringing additional business advantages. So, let’s look at what the experts have to say.

How thought leaders see logistics decarbonised

Diving deeper into the specifics, we find invaluable insights from thought leaders like the eco-conscious logistics firm CHEP, ALICE, the ´Alliance for Logistics Innovation through Collaboration´ in Europe, and Professor Alan McKinnon. According to CHEP , truck electrification is expected to play a significant role in about a decade. While ten years may seem distant, especially when urgent climate action is needed, we must acknowledge the reality.

Commercialising new technologies often requires substantial CAPEX investments and time, not to mention the need for willing investors. Thus, for immediate action, we should focus on the most effective tools and readily available solutions. For supply chain improvement and reducing carbon, we must focus on better load planning, combining shipments, and improving route efficiency. A key method recommended by CHEP is double-stacking pallets. According to CHEP this method increases transport space by a notable 41%.

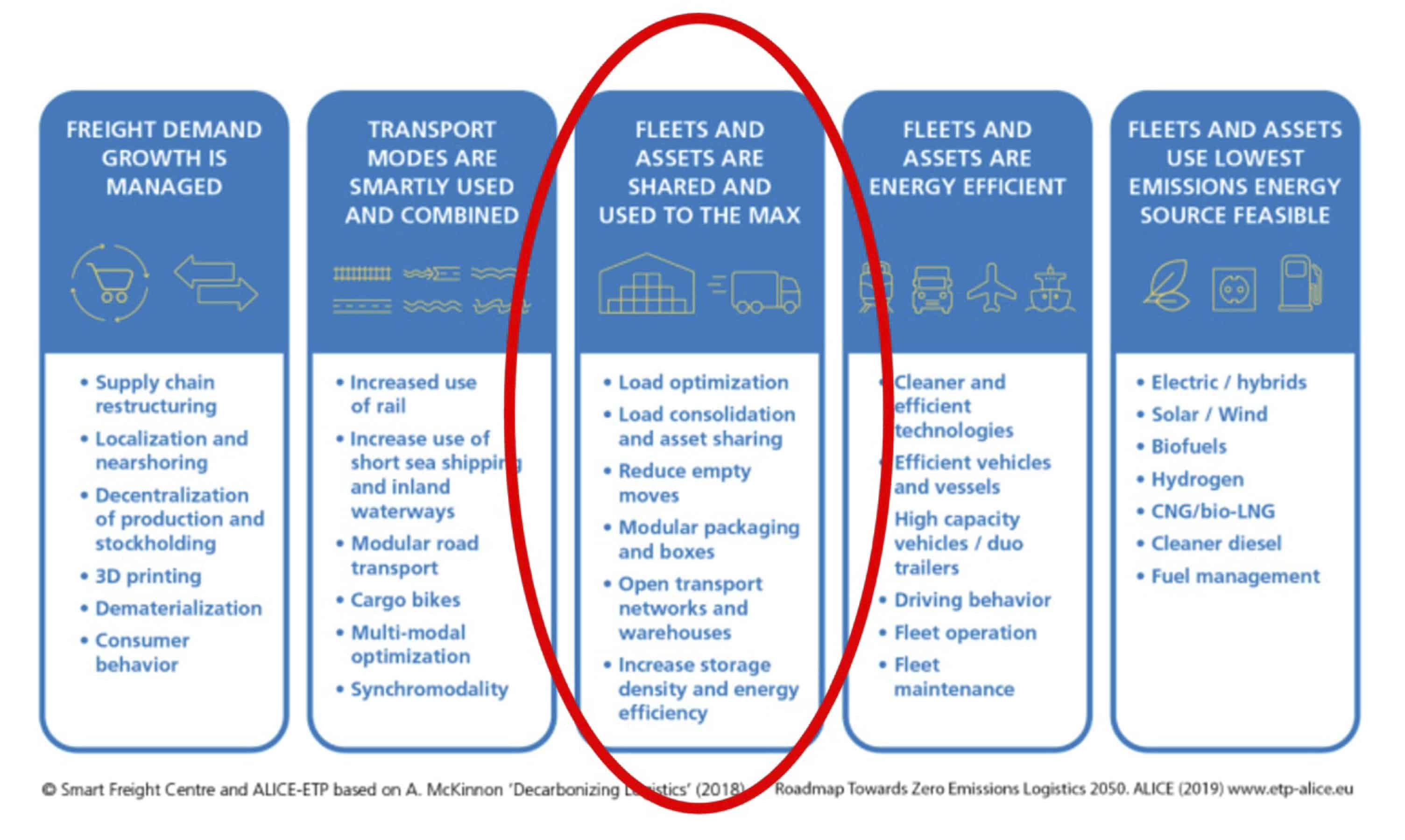

This sentiment resonates with the findings of Professor Alan McKinnon in his extensive research and very influential book “Decarbonising Logistics – Distributing Goods in a Low Carbon World”, (2018) . According to McKinnon logistics accounts for around 9-10% of global CO2 emissions. This significant contribution is partly due to the expected sharp rise in demand for freight transport in the coming decades and the sector’s heavy reliance on fossil fuels. McKinnon has developed a five step model to “Decarbonising Logistics” as illustrated in fig. 1 below by previously mentioned ALICE – showing that much decarbonisation can be done here and now.

Representing decarbonisation solutions to the transport and logistics industry, our focus lies on McKinnon’s central three pillars, aiming to scale up for greater impact. And if we zoom in on the red circled middle column specifically, the potential for decarbonisation becomes unmistakably clear.

McKinnon underscores the undeniable connection between maximising road freight capacity and achieving significant carbon reduction, as illustrated by the concrete examples and optimisation tools already discussed. Inefficiencies from underutilised truck space directly result in increasing CO2 emissions. His approach resonates with the principles of foresight, efficiency, collaboration, and innovation in load optimization. Utilising strategic route planning, adhering to precise loading practices, and leveraging data analytics are all crucial for ensuring optimal truck utilisation.

Our Vision

At SpaceInvader, we’re dedicated to navigating the challenges ahead. We see the overlap of environmental responsibility and cost efficiency more as a business opportunity than a hurdle. The move toward circularity and sustainability isn’t just about being eco-friendly; it’s the foundation of the next phase of smart business. Through supply chain innovation, businesses can achieve both cost savings and reduced CO2 emissions.

This perspective isn’t unique to us. Forward-thinking businesses worldwide are already recognising the importance of aligning environmental efforts with strategic financial decisions. However, it is essential to understand that making a real difference isn’t a solo journey. True progress involves collaboration among manufacturers, transporters, retailers, and even policymakers and regulators.

The SpaceInvader DNA is green, and we firmly believe that our green-tech solution is a part of society’s circular and sustainable economy, as outlined below.

SpaceInvader in Action

Our initiatives are guided by expert, technical, and operational insights, and learnings from working closely with our customers. Our offerings include a state-of-the-art pallet rack double-stacking solution bolstered by solid and customised data analytics, along with tailormade implementation and change management programs. These are grounded in robust industry knowledge and designed to boost road transportation efficiency.

Hence, the evidence is clear. The environmental advantages are clear, and the financial benefits are equally strong. In fact, these two aspects align closely: cost efficiency and decarbonisation can be achieved in tandem. By making smart investments in both CAPEX and OPEX, companies can realise significant value.

The Sustainable Road Ahead

While the journey to net-zero emissions might seem daunting, the incremental benefits of each strategic decision compound over time. Through the synergies of innovation and collaboration, businesses can not only meet but exceed their climate commitments.

Tackling supply chain decarbonisation is crucial yet exciting. Our customers are a clear testament to this, reducing CO2 emissions and costs by 15-25% through smarter freight capacity management. Tools like the SpaceInvader pallet system score a double win: they boost both environmental outcomes and the bottom line, proving that green logistics is not only viable but smart business.

As we wrap up, let’s keep in mind the impact of our choices. Opting for particular brands and services today shapes not only our immediate bottom line but also the legacy we leave. Our decisions, especially in sustainability, are about more than us; they’re about the choices we make today – not tomorrow’s promises – and ultimately, about the world we pass on to future generations.